To understand how this device can produce such complex and precise products, it’s essential to grasp the 3D printer structure and its working principles. The following article by 3Dmanufacturer will walk you through the technical composition of a 3D printer, along with its practical applications in healthcare.

What is a 3D printer?

A 3D printer is an advanced device that creates three-dimensional objects based on digital designs. Instead of printing ink on paper like traditional printers, 3D printers use special materials to build objects layer by layer, accurately reproducing their shapes and structures.

Unlike 2D printing, which only presents images on a flat surface, the 3D printer structure allows for the creation of physical models with depth, width, and height. This capability enables users to quickly produce prototypes, parts, or finished products.

The emergence of 3D printers has opened new opportunities across industries – from mechanical engineering and regenerative medicine to STEM education and artistic design. The ability to turn ideas into reality in a short time has made 3D printing a powerful tool in the digital era.

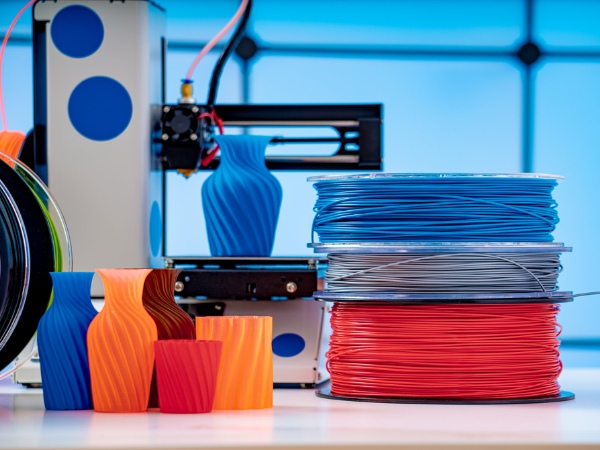

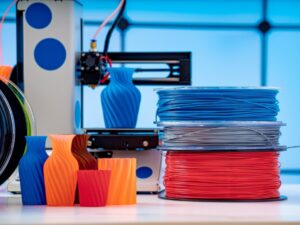

Structure of a 3D printer

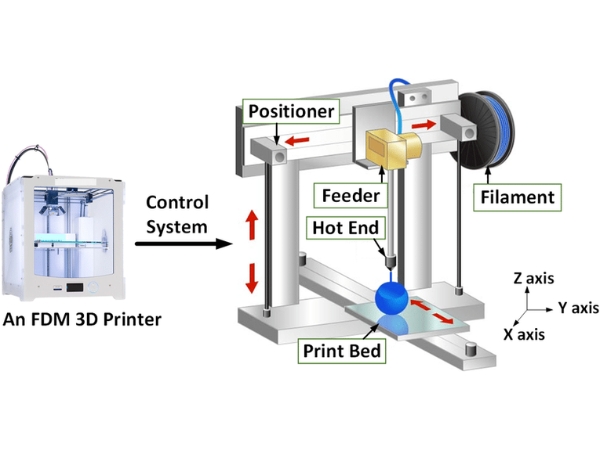

Today’s 3D printers are developed using various technologies such as FDM, SLA, and SLS. Among them, FDM-based printers are the most common due to their low cost and ease of use. Although the specifics vary by technology, most 3D printer structures include the following core components:

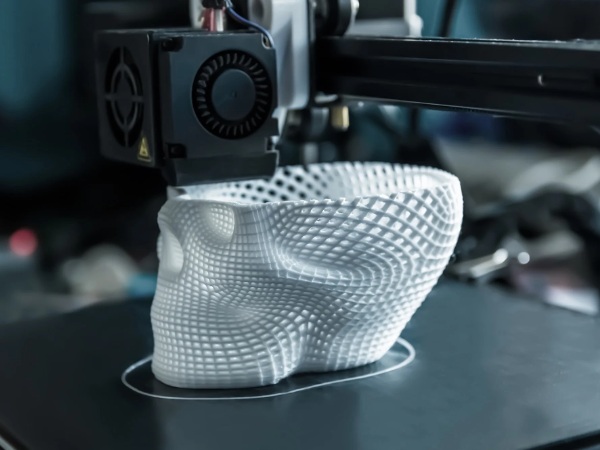

Print head and extrusion system

The print head and extrusion system heat the printing material (usually filament plastic) to its melting point. Once melted, the material is extruded through a nozzle and deposited layer by layer. The nozzle diameter and extrusion speed determine the printing resolution and time.

Build plate and Z-Axis

In the 3D printer structure, the build plate is where the object is gradually constructed layer by layer. The Z-axis mechanism adjusts the height of either the build plate or the print head after each layer, ensuring precise layer alignment. Accurate Z-axis control directly impacts the vertical resolution of the final product.

XY-Axis motion system

The print head moves along the X and Y axes to form each 2D slice of the model. The precision of this movement system – consisting of rails, stepper motors, and sensors – is crucial to shaping the overall geometry of the printed object.

How 3D printing technology works

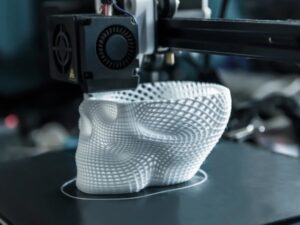

3D printers operate based on the principle of additive manufacturing, a process in which material is layered consecutively to form a complete three-dimensional object.

The process starts with a 3D digital model, typically designed using CAD (Computer-Aided Design) software. This model is then converted to an STL file or another compatible format for printing. The STL file describes the object’s geometry using a mesh of triangles, allowing slicing software to analyze and divide the model into hundreds or thousands of thin layers.

During printing, slicing software generates precise toolpaths for the print head at each layer. The printer heats the material (commonly thermoplastics like PLA or ABS) until it melts. The print head moves along the XY axes, extruding material according to the programmed path. After each layer, the control system lifts the build plate via the Z-axis (or lowers the print head, depending on the printer design), allowing the next layer to be printed on top.

This cycle repeats until the entire model is constructed, with its shape and dimensions matching the original design.

Applications of 3D printing in the medical field

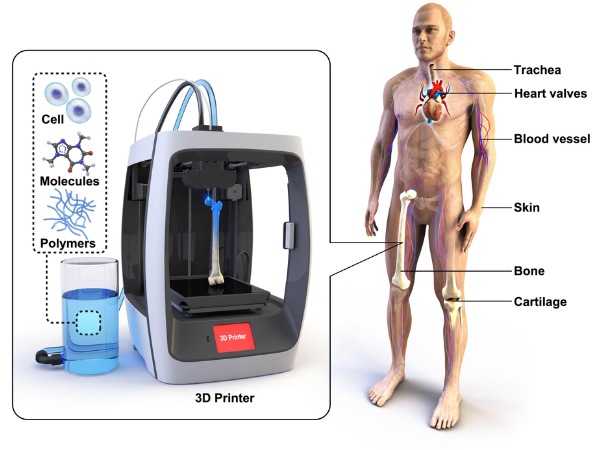

Thanks to the 3D printer structure that allows for accurate modeling based on medical imaging data such as MRI or CT scans, 3D printers can produce anatomical structures, treatment aids, body parts, and customized medical tools. This contributes to personalized treatment plans and improved clinical outcomes.

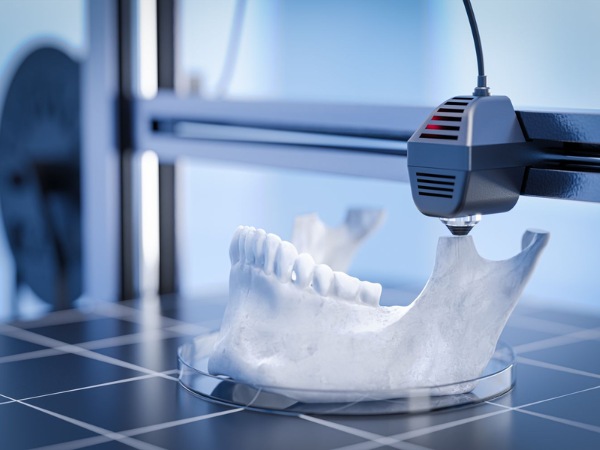

Implant fabrication

3D printing is revolutionizing implant manufacturing – from dental to orthopedic applications. Using patient-specific data, technicians can design implants that are fully compatible with the patient’s anatomy, increasing accuracy, reducing rejection rates, and shortening recovery times. High-precision models such as dental posts, knee joints, or artificial vertebrae can be printed with ease.

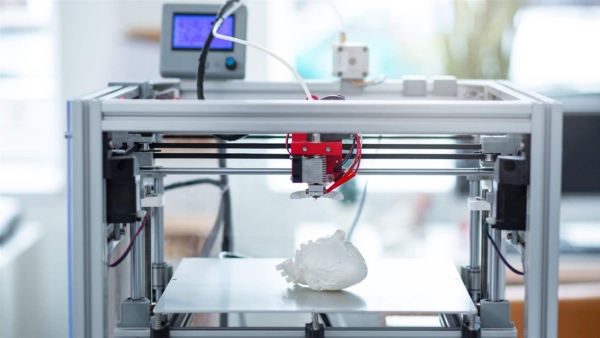

Surgical simulation and medical training

3D printers can produce realistic anatomical models based on patient data to support preoperative planning. Instead of relying solely on digital images, doctors can physically interact with the model to improve precision and anticipate potential challenges during surgery. These models are also highly effective in training young surgeons, allowing hands-on practice with life-like anatomy.

Custom surgical instrument manufacturing

Thanks to 3D printing, designing and producing surgical tools for specific cases becomes feasible. Instruments such as scalpels, bone-cutting guides, or positioning devices can be quickly fabricated with custom designs for each case. This reduces preparation time and enhances precision during procedures, minimizing tissue damage and speeding up recovery.

Personalized prosthetics printing

Unlike traditional methods that require extensive manual adjustment and time, 3D printing enables the production of prosthetics with complex, aesthetic structures tailored to individual users. These parts can be printed using various materials, including titanium, lightweight metals, or thermoplastics such as PLA, PETG, or TPU.

Medical device design optimization

Before mass-producing medical equipment like ventilators, endoscopic tools, or casings for diagnostic machines, 3D printing allows for rapid prototyping to test functionality, refine design, and ensure ergonomic fit. Technologies like FDM or SLA are particularly suitable for printing plastic components before moving to metal or composite manufacturing.

Bioprinting and regenerative medicine

One of the most advanced trends is using 3D printing to create living tissues with biological materials – known as bioprinting. These materials act as scaffolds that support cell growth and tissue regeneration in controlled environments. This application holds great promise for producing artificial skin, cartilage, liver tissue, or even cardiovascular structures for research and treatment.

Despite its breakthroughs, the use of 3D-printed products in healthcare must strictly comply with safety standards. All materials and devices that come into direct contact with the human body must be tested and approved by regulatory bodies like the FDA (USA) or CE (Europe). Operating the printer and post-processing also require trained technicians to ensure biological safety.

Understanding the 3D printer structure not only optimizes how the device is used but also opens up many opportunities for innovation and future development in the healthcare sector. From surgical planning models and customized medical tools to prosthetics and personalized implants, this technology is helping reduce treatment times, lower costs, and improve patients’ quality of life.

Are you looking for medical-grade 3D printing solutions? Let 3Dmanufacturer be your trusted partner! We provide professional 3D printing services using rigorously tested medical-grade materials, suitable for applications in surgery, orthopedics, dentistry, and many other advanced medical fields. With extensive experience from real-world projects, 3Dmanufacturer is committed to delivering optimal solutions – from prototyping and trial printing to the production of customized medical devices.