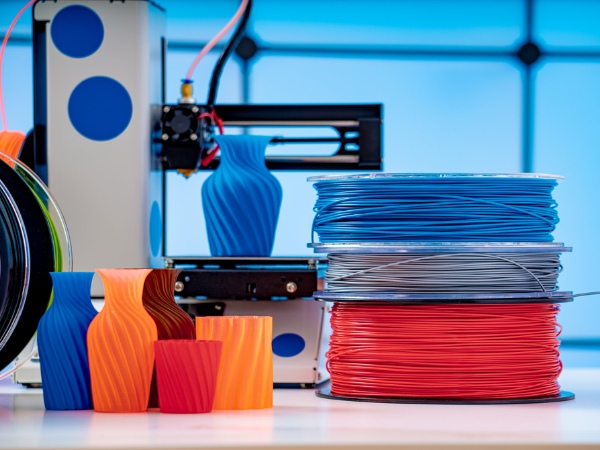

Knowing how to choose 3D printing filament has a direct impact on the print quality, durability, and dimensional accuracy of your final product. Each specific application requires a different filament type tailored to its physical properties and compatibility with your printer. In this article, 3Dmanufacturer will guide you through the most effective way to select the right 3D printing material for various use cases – while helping you avoid common errors that could damage your printer or compromise your finished object.

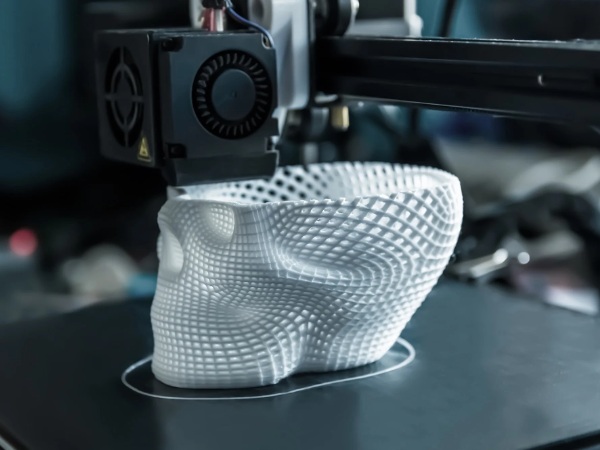

3D print quality starts with the filament you choose

Selecting the right material is essential – but to achieve consistent print quality, it’s even more important to choose 3D printing filament that matches your specific needs. Using low-quality materials may lead to several issues, from fragile, brittle objects and air bubbles to poor surface finishes and layer inconsistencies. These flaws not only reduce visual appeal but also significantly weaken the mechanical strength of the printed parts.

Furthermore, substandard filaments may damage your printer, with common problems including nozzle clogging, residue buildup that wears out components, and shortened equipment lifespan. In some cases, materials with unknown additives may emit toxic fumes during printing, posing health risks to operators – especially dangerous if the final products are intended for medical or food-related use.

Key factors to consider when choosing 3D printing filament

Choose 3D Printing Filament based on your specific application, technical requirements, and safety standards – this is a smart first step to ensure long-term performance for both products and equipment.

Intended application

Defining your purpose clearly helps filter out filament types that meet particular demands in mechanical properties, strength, or aesthetics.

- For display pieces or simple models, easy-to-print filaments like PLA are sufficient.

- If you’re printing technical parts, machine components, or load-bearing items, consider ABS, PETG, or Nylon.

- For flexible applications that require elasticity and shape recovery, TPU is worth considering.

- For heat-resistant use cases (e.g., electrical housing), PC or Nylon perform better.

3D printing technology used

Compatibility between filament type and printing technology is essential.

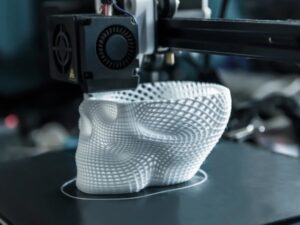

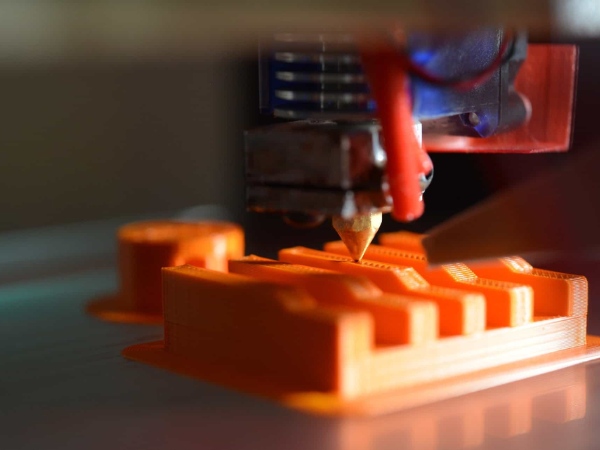

- FDM technology works with filament spools like PLA, ABS, PETG, TPU, etc. These materials differ in melting points and layer adhesion, affecting layer quality.

- SLA/DLP printers use liquid resin for ultra-high-detail prints, ideal for smooth and intricate models.

- SLS technology requires powder-based materials like Nylon PA12 for complex or high-volume production needs.

Cost and economic efficiency

The cost of 3D printing filaments varies significantly depending on material properties, brand, and origin. For small-scale projects or prototypes, budget-friendly options like PLA or PETG are suitable. High-performance engineering plastics such as PC or Nylon are more expensive and require specialized printers, making them a worthwhile investment only for demanding applications.

Printer compatibility and ease of use

Not all filaments are easy to work with. Differences in melting points, bed adhesion, and warping behavior mean that some materials are better suited for experienced users.

Beginners are usually advised to start with PLA, as it has low shrinkage, prints easily, and is less error-prone.

On the other hand, filaments like ABS or Nylon offer strong mechanical benefits but require enclosed chambers, stable temperatures, and strict storage conditions. Choosing a filament compatible with your printer’s capabilities will reduce print failures.

Safety and environmental impact

When selecting 3D printing materials, safety and environmental impact must not be overlooked. Certain filaments may release harmful fumes during melting, which can be risky if used in poorly ventilated areas. Some materials may also cause skin irritation upon contact. Therefore, always evaluate safety ratings and environmental friendliness when making your selection.

Comparison of Popular 3D Printing Filaments

Before choosing a 3D printing filament, it’s important to understand the properties of each type to ensure the final product meets your expectations in terms of precision, strength, and aesthetics. The table below compares popular 3D printing filaments based on printability, mechanical strength, heat resistance, and common applications:

| Filament Type | Strength & Flexibility | Heat Resistance | Common Applications | Notes |

| PLA | Good, but brittle | Poor (~60°C) | Models, toys, decor | Not suitable for high-heat/mechanical use |

| ABS | Good, strong | Good (~100°C) | Casings, appliances | Needs enclosed printer, prone to warping |

| PETG | Excellent | Good (~75–85°C) | Functional parts | Balanced choice between PLA and ABS |

| TPU | Very flexible, elastic | Moderate | Phone cases, wheels | Requires compatible extruder (not ideal for Bowden) |

| Nylon | Highly durable, wear-resistant | Excellent (~120°C) | Gears, bearings | Strong moisture absorption, needs careful storage |

| PC (Polycarbonate) | Very strong | Excellent (~110–120°C) | Industrial, structural parts | Requires high temp, prone to warping |

| PET | Rigid, good strength | Good (~80°C) | Consumer goods | No heated bed needed, glossy finish |

Tips for choosing the right 3D printing filament for your application

With countless 3D printing materials available, picking the right filament can be overwhelming – especially for beginners. Here are some practical tips to simplify the process:

Consult the 3D printing community

Getting input from experienced users saves time and helps you avoid mistakes. Communities like Reddit, Facebook groups, and websites such as 3Dmanufacturer, Makerbot, or 3D Modeling Shop often share real-world reviews, pros and cons of each filament, and the latest material trends.

Watch Hands-On review videos

YouTube content is highly visual and lets you observe each filament’s properties in action – from layer adhesion and flexibility to surface finish. Channels like 3Dmanufacturer, Meme3D, or Technick Am are great starting points for deeper insights into filament behavior.

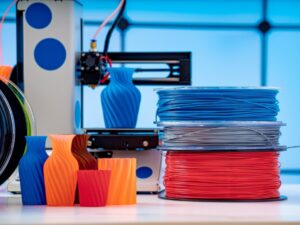

Start with small sample packs

Instead of buying large spools, try smaller samples first. This helps reduce costs and lets you test compatibility with your printer and product quality before committing to bulk purchases.

Fine-Tune print settings for each material

Each filament requires specific settings – nozzle temperature, bed temperature, print speed, etc. Following manufacturer-recommended configurations minimizes errors and improves output quality. Take time to review technical documentation or online guides for your chosen filament.

Choosing 3D printing filament wisely is a foundational step that helps save time, reduce costs, and ensure long-term printing success. Whether you’re a beginner or an experienced maker, evaluating your usage needs, printing technology, and hardware capabilities will help you avoid costly mistakes. Stay informed, test materials selectively, and always optimize your print settings for each filament type!