Thermoplastic is one of the most important and commonly used materials in 3D printing technology. It has the ability to melt when heated and solidify when cooled without changing its chemical structure, offering excellent flexibility in manufacturing and reuse. So, what exactly is thermoplastic and why has it become a preferred material in 3D printing? Let’s explore together with 3Dmanufacturer right now!

What is Thermoplastic?

Thermoplastic (also known as thermoplastic resin) is a type of polymer material that becomes soft and easily moldable when heated. This material is made from polymers (large molecules), which are formed by monomers (smaller units) linked together in a linear arrangement.

The length of the polymer chains determines many important properties of thermoplastics: the longer the chains, the higher the molecular weight, which corresponds to greater strength and load-bearing capacity of the material.

One of the most outstanding features of thermoplastics is their ability to melt and be reshaped repeatedly without degradation. When heated to an appropriate temperature, thermoplastic can be molded, pressed, or printed into any desired shape, then hardens upon cooling while retaining its physical properties.

Common Types of Thermoplastics

There are many different types of thermoplastics, each widely used across various industries today. Each type has its own distinct properties suitable for specific applications.

- Acrylic (PMMA): Known for its transparency and high impact resistance, acrylic is often used as a glass substitute in products like LCD screens, automotive headlights, premium furniture, coatings, and optical lenses.

- Polyethylene (PE): Mainly divided into two types – LDPE (low density), commonly found in flexible packaging, plastic bags, and bottles; and HDPE (high density), used for children’s toys, outdoor playground equipment, and construction materials due to its superior strength.

- Polyvinyl Chloride (PVC): This plastic offers excellent chemical resistance and electrical insulation, widely used in industry and everyday life – from electrical cables, water pipes, roofing materials, flooring, wall panels, to medical devices.

- Polypropylene (PP): Valued for its mechanical strength and heat resistance, PP is commonly found in food containers, packaging, machinery parts, and technical plastic components.

- Polycarbonate (PC): A plastic with excellent mechanical and optical properties, suitable for high-safety applications such as eyewear, medical devices, personal protective equipment (PPE), greenhouses, CDs/DVDs, and electronic components.

- Polystyrene (PS): Lightweight and easy to mold, PS is an ideal choice for packaging, food trays, toys, disposable containers, and foam cups.

- Polytetrafluoroethylene (PTFE or Teflon): Known for its non-stick and high heat resistance, PTFE is commonly used in non-stick cookware, waterproof fabrics, electronic components, and self-cleaning ovens.

- Foam (Expanded plastics): With thermal insulation and impact absorption properties, foam is widely used in building insulation, packaging, and disposable products like plates and trays.

- Polyamide (Nylon): Renowned for its tensile strength and abrasion resistance, nylon is widely applied in textiles (clothing, tents), automotive industry (tires), as well as rope and fishing net production.

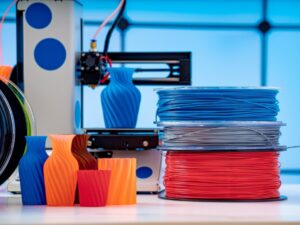

Thermoplastic Materials in 3D Printing Technology

In 3D printing, thermoplastics play a crucial role as base materials, especially when blended to create compounds that combine the hardness of plastics with the elasticity of rubber.

Currently, the market offers a wide variety of thermoplastic types for 3D printing, differing in technical properties and filament sizes. Among these, the two most popular are TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer). Below are some outstanding advantages of these two materials:

- Impressive Elasticity: TPU and TPE can be stretched or bent significantly without cracking, allowing the creation of flexible yet sturdy parts.

- Good Impact Resistance: Thanks to their rubber-like elastic structure, objects printed from TPU and TPE can effectively absorb impacts, minimizing damage from collisions or drops during use.

- Vibration Absorption: Their damping properties and ability to reduce vibrations make these plastics ideal for technical applications – especially mechanical parts, electronic components, or machine parts that require high durability and flexibility.

Differences Between Thermoplastics and Thermosetting Plastics

The fundamental difference between thermoplastics and thermosets lies in their response to temperature and molecular structure after processing.

| Criteria | Thermoplastics | Thermosets |

| Molecular Structure | Polymer chains can separate when heated; no permanent chemical reaction

|

Cross-linked structure that cannot be broken after curing |

| Response to Heat | Can melt when heated and solidify when cooled | Harden permanently after one heating; cannot be remelted |

| Recyclability | Can be recycled and reused multiple times | Cannot be recycled by conventional thermal methods |

| Heat Resistance | Poor heat resistance; easily deforms at high temperatures | Excellent heat resistance; stable in harsh environments |

| Chemical Corrosion Resistance | Medium to high (depending on type) | High, especially in technical and industrial applications |

| Flexibility | Very flexible and easy to process; suitable for 3D printing and rapid prototyping | Less flexible; difficult to process after curing |

| Applications | Used for packaging, consumer plastic products, 3D printed parts, lightweight technical materials | Suitable for electrical equipment, circuit boards, insulating materials, heat-resistant components |

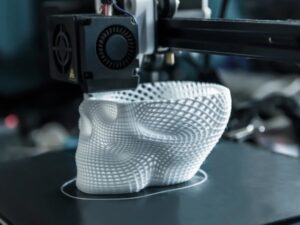

Applications of Thermoplastic Materials in 3D Printing

Below are some typical applications of thermoplastics in 3D printing and why they are increasingly favored in both laboratory settings and large-scale production lines.

- Functional Prototyping: Thermoplastics enable the printing of products or components with high elasticity, making them ideal for testing functionality and flexibility under real-use conditions. This is an effective solution for quickly evaluating the performance and design of a product before moving to mass production.

- Flexible tool customization: Thanks to its pliable and easily bendable properties, thermoplastic filament helps create tools with good grip, tailored to specific usage purposes.

- Manufacturing protective parts for equipment and machinery: Thermoplastics, especially TPU, are used to produce components that protect devices from impacts or damage. Thanks to their elasticity and shock-absorbing properties similar to rubber, these materials are ideal for creating soft contact points, helping to minimize the risk of damage in production lines.

Frequently Asked Questions

To help you better understand and use thermoplastics effectively, below are some common questions along with detailed answers based on current technical knowledge and practical applications.

- Can thermoplastics be recycled?

Yes. Thermoplastics are very easy to recycle because when heated, their polymer chains do not break but only separate at weak bonds. This allows the material to be melted and reshaped multiple times without losing its fundamental properties.

- Are thermoplastics safe?

Most types of thermoplastics are safe when used properly. However, some concerns have been raised about PVC due to the presence of vinyl chloride monomer (VCM). Nevertheless, modern manufacturing processes strictly control residual VCM levels, keeping them extremely low and posing no significant health risk to users.

- Are thermoplastics biodegradable?

Most thermoplastics are not biodegradable. However, there are some environmentally friendly types such as PLA (polylactic acid), PVAL (polyvinyl alcohol), and PHA (polyhydroxyalkanoates) that can biodegrade under appropriate conditions.

- Are thermoplastics brittle?

The brittleness of thermoplastics depends on temperature. Below their glass transition temperature (Tg), the material tends to be brittle and prone to breaking. Above Tg, they become more flexible and capable of plastic deformation, making them easier to process.

- Can thermoplastics be remolded?

Yes. This is a key feature of thermoplastics: the material can be melted and reshaped into new forms without losing its original characteristics.

- Can thermoplastics be welded?

Yes. Thermoplastics can be welded using various techniques such as hot welding, ultrasonic welding, or laser welding, depending on the type of material and specific application.

- Can thermoplastics be painted?

Thermoplastics can definitely be painted to achieve aesthetic finishes or protection. However, choosing the right type of paint is very important to avoid chemical reactions that cause fading or reduced durability. Acrylic-based paints, especially spray paints, are usually a safe and effective choice.

- Can thermoplastics melt?

Yes, but it depends on their structure. Semi-crystalline thermoplastics have a clear melting point where crystalline regions break down. In contrast, amorphous thermoplastics do not melt in the traditional sense; they gradually soften above their glass transition temperature, changing from a brittle state to a rubber-like flexible state.

Thermoplastic is an important material in modern industry. With its recyclability, ease of processing, and design flexibility, thermoplastic opens up many creative possibilities for manufacturing – from individual projects to industrial-scale production. If you have any questions about this material, contact 3Dmanufacturer for expert answers!