DMLS (Direct Metal Laser Sintering) is a breakthrough technology in metal 3D printing, enabling the creation of complex and durable parts that traditional methods cannot achieve. In this article, 3Dmanufacturer will take a closer look at what 3D DMLS printing is, its advantages and disadvantages, and why it is so important in the modern 3D printing industry.

What is DMLS Technology?

DMLS (Thiêu kết laser kim loại trực tiếp) là một trong những công nghệ in 3D tiên DMLS (Direct Metal Laser Sintering) is one of the most advanced 3D printing technologies available today in the field of metal manufacturing. This technology uses a high-powered laser to melt and fuse successive layers of metal powder according to the design from a 3D CAD model, creating parts with complex shapes, high precision, and superior mechanical properties.

Thanks to its ability to print directly from digital designs, DMLS is especially ideal for producing functional prototypes, specialized tools, medical implant components, and aerospace parts – where meticulous detail, high accuracy, and strong load-bearing capacity are critical.

What are the advantages and disadvantages of 3D DMLS printing?

DMLS is not only a significant breakthrough in 3D printing but also opens the possibility of manufacturing complex parts with high precision. However, alongside these impressive advantages, there are several limitations to consider before deciding to invest.

Advantages

The DMLS metal 3D printing technology offers many outstanding benefits:

- Fast production speed: The prototyping and manufacturing process is quicker compared to many other production technologies.

- Reasonable investment cost: Among rapid prototyping technologies, DMLS is one of the metal 3D printing methods with the lowest initial investment costs.

- Material savings: Efficient use of metal powder helps significantly reduce material costs.

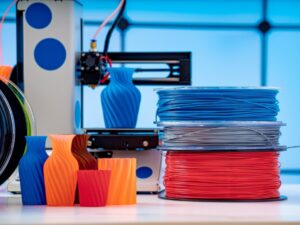

- Wide range of materials and applications: From stainless steel and titanium to aluminum alloys, DMLS can print many types of materials, serving diverse industries.

- Ability to print complex details: DMLS can manufacture intricate structures without the need for support scaffolds, optimizing product design.

- User-friendly operation: Modern DMLS printers are designed to be user-friendly, easy to install, operate, and maintain.

- Versatile prototyping: Allows printing products in various colors and sizes, suitable for specific applications.

Disadvantages

Despite its many advantages, DMLS technology still has certain limitations:

- Competition with traditional technologies: In many cases, CNC machining or molding remains a more efficient and cost-effective method for mass production.

- High cost per product: Compared to traditional manufacturing methods, the cost of DMLS printing for each part can be higher if not optimized.

- Size limitations: Currently, parts printed with DMLS are usually limited to an area of about 1.5 square meters.

- Requirement for specialized materials: To achieve optimal print quality, specialized metal powders with high purity and uniform particle size are necessary.

- High energy consumption: The high-power laser requires a significant amount of energy throughout the sintering process.

- Demanding technical skills: Operating a DMLS machine is complex, requiring operators to be thoroughly trained and technically proficient.

- Need for support structures: Some designs still require support structures during printing to ensure stability.

Operating Principle of DMLS Technology

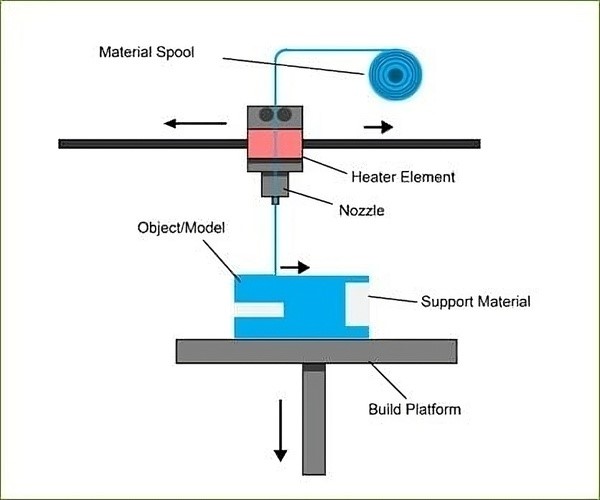

DMLS (Direct Metal Laser Sintering) 3D metal printing technology works based on the principle of using a high-power laser to melt metal powder layer by layer, following a pre-designed 3D model. The basic process involves the following steps:

- Preparing the Printing Chamber and Materials

Before starting the printing process, the build chamber is filled with an inert gas, usually argon or nitrogen. This prevents oxidation when the metal powder comes into contact with air at high temperatures, thereby preserving the material quality throughout the sintering process. Simultaneously, the chamber is heated to an optimal temperature to help the metal powder bond more easily and reduce deformation during printing.

- Layer-by-Layer Laser Sintering

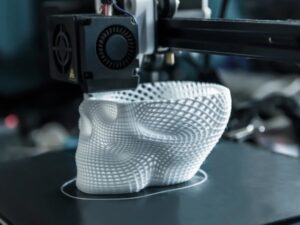

The printing process begins by spreading a very thin layer of metal powder evenly across the build platform. Then, a high-power laser scans the cross-section of the 3D model layer by layer, melting and fusing the metal powder particles together to form the desired shape.

Each laser pass creates a solid layer, and the entire part is built by repeating this process hundreds or thousands of times, according to the predetermined layer thickness (typically several tens of microns).

- Completing the Build

After a layer is finished, the build platform lowers by exactly one layer thickness, and a new layer of powder is spread on top. This cycle repeats until the entire part is fully formed according to the 3D design.

Unlike SLS (Selective Laser Sintering) polymer printing, parts printed by DMLS always require support structures due to the very high sintering temperature of metals. These supports help minimize warping and distortion while stabilizing the part during fabrication. The supports are printed using the same metal material as the main part.

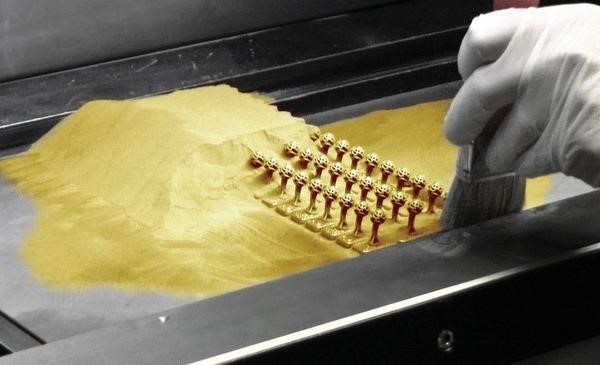

- Cooling, Cleaning, and Post-Print Heat Treatment

Once printing is complete, the build chamber is gradually cooled to room temperature. The printed parts remain embedded in the unused powder. The leftover powder is manually or mechanically removed for reuse in subsequent prints.

Before detaching the parts from the build platform, they typically undergo heat treatment to relieve residual stresses accumulated during sintering, stabilizing the microstructure and improving mechanical properties.

- Finishing the Parts

Finally, the parts are separated from the build platform by mechanical cutting, CNC machining, or wire EDM cutting. Depending on the application requirements, the 3D printed parts may undergo polishing, plating, painting, or surface treatment to enhance aesthetic appearance or technical performance.

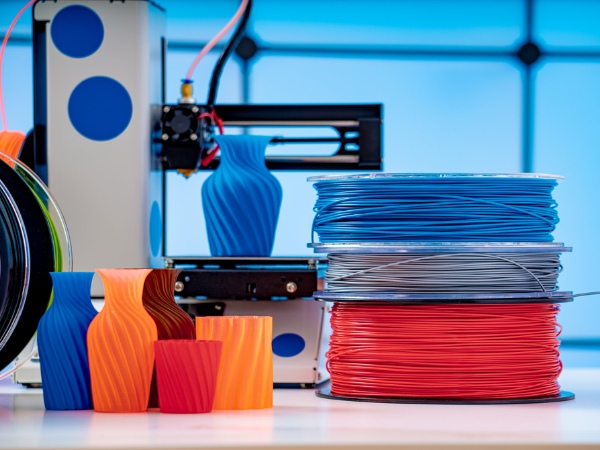

Practical Applications of 3D DMLS Printing

DMLS (Direct Metal Laser Sintering) 3D printing technology is increasingly proving its vital role across various industrial fields due to its ability to produce metal parts with high complexity, absolute precision, and superior mechanical properties. These applications include:

- Medical Field: In healthcare, 3D DMLS technology is used to print custom components such as prosthetic limbs and bone implants tailored to the patient’s bone structure. These parts feature controlled porosity that facilitates real bone growth and integration with the implant.

- Aerospace Industry: DMLS enables the manufacturing of complex parts such as turbine components, exhaust nozzles, aerodynamic probes, and even integrated structural assemblies that traditional machining methods cannot achieve. By eliminating the need for molds, DMLS reduces the number of parts and overall weight while maintaining high stiffness, durability, and safety.

- Dental Industry: 3D DMLS printing is applied to produce dental restorations such as crowns, bridges, and partial dentures based on 3D scans of the patient’s oral cavity. These parts are printed using cobalt-chromium alloys that offer excellent strength and corrosion resistance in the oral environment.

Comparison Between DMLS and Other 3D Printing Technologies

In the field of metal 3D printing, DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) are two prominent technologies within the powder bed fusion group. Although they share many similarities, there are important differences in their operating principles and application scopes.

Similarities

- Both technologies build parts layer by layer, stacking thin layers to form a complete component.

- DMLS and SLM use lasers to scan and process each cross-section of the 3D model, bonding or melting metal powder according to the CAD design.

- Both operate using metal powders, including stainless steel, titanium, aluminum, cobalt-chrome, and various other technical alloys.

- Parts produced by DMLS or SLM exhibit extremely high precision, making them ideal for industrial applications that require tight tolerances and strong mechanical performance.

Differences

The key difference between 3D DMLS and SLM lies in how the metal powder is processed:

- SLM technology requires metal powders with a defined melting point, such as pure metals or homogeneous alloys. The laser completely melts the powder particles, which then solidify into a fully dense, solid structure.

- DMLS technology is based on sintering the powder particles at high temperatures without fully melting them. This method suits materials with multiple metal phases or complex alloys, allowing better control over deformation and residual stresses during printing.

- Additionally, DMLS and SLM were developed by different companies, each with proprietary technologies and application focuses. Each holds distinct patents, leading to technical differences and terminology variations.

Frequently Asked Questions

For many people, 3D DMLS printing is still a relatively new technology. Below are some common questions users often ask when learning about and starting to apply DMLS metal 3D printing technology:

How thick are the material layers in DMLS?

The thickness of each material layer during the DMLS printing process can vary depending on the type of printer and the specific project requirements. However, typically, these layers range in thickness from 16 micrometers to 150 micrometers.

What is the difference between sintering and melting?

Sintering heats the metal powder below its melting point and maintains that temperature for a period to allow the particles to bond together through atomic diffusion. In contrast, melting raises the temperature above the melting point of the material, causing the powder particles to fully melt and fuse together as they cool, resulting in a more solid and dense structure.

What types of metals are used in 3D DMLS printing?

DMLS can utilize a wide variety of metals for 3D printing, including both pure metals and technical alloys:

- Stainless steel

- Aluminum alloys

- Nickel-based alloys

- Titanium alloys

- Copper

- Tungsten

- Specialized alloys used in medical, aerospace, automotive, or defense industries.

Through this article, you should now have a clear understanding of what 3D DMLS printing is and why this technology is becoming a breakthrough trend in modern metal 3D printing. With its precise shaping capabilities, durable materials, and wide applications in medical, aerospace, mechanical engineering, and more, DMLS is the optimal choice for advanced engineering projects. If you are looking for professional 3D DMLS printing solutions, contact 3Dmanufacturer — the hub of cutting-edge technology and an experienced technical team, ready to bring your ideas to life!