What is CAD, and why has it become an indispensable tool in modern engineering design? In the context of growing industrialization and automation, CAD (Computer-Aided Design) plays a vital role in assisting engineers and designers in creating technical drawings that are accurate, intuitive, and efficient. From mechanical engineering and construction to electronics and industrial design, CAD software is increasingly widely applied, helping to enhance productivity, minimize errors, and optimize the manufacturing process.

Nội dung

What is the definition of CAD?

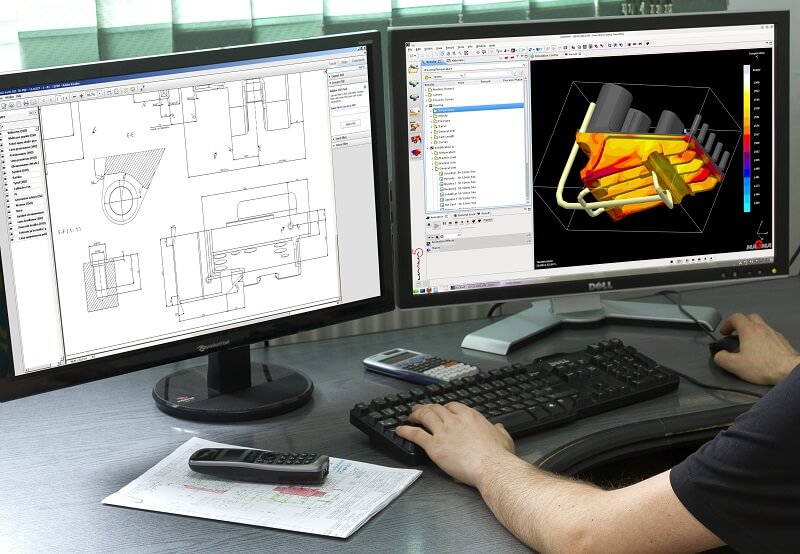

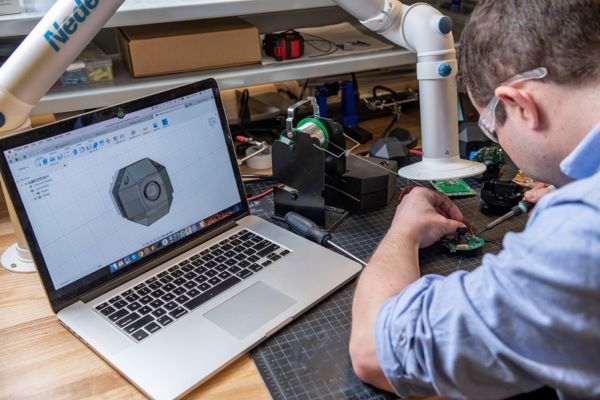

CAD (Computer-Aided Design) is a computer-based design software system that allows users to efficiently visualize, edit, and analyze 2D and 3D technical drawings. This technology is widely used across various fields such as architecture, construction, mechanical engineering, manufacturing, and industrial design.

Thanks to CAD, engineers and designers can create highly accurate drawings and models, significantly reducing design time compared to traditional methods like hand drafting. The system also supports the development of 3D models and technical documentation, enabling users to clearly visualize the structure and function of a product before moving into the production phase.

Notably, CAD can integrate data from multiple sources such as 3D scanners, CAM (Computer-Aided Manufacturing) software, and CNC (Computer Numerical Control) systems, creating a flexible and synchronized workflow. In the field of CNC machining, CAD plays a pivotal role in producing highly precise and high-performance products.

Some common benefits of using CAD

In the modern machining industry, especially in CNC machining, Computer-Aided Design (CAD) software has become a familiar and indispensable tool. CAD not only assists engineers and designers in creating technical models but also plays a central role in enhancing the quality and efficiency of the entire manufacturing process. So, what makes CAD software so important?

Outstanding benefits of applying CAD in design and manufacturing:

- Increased productivity and optimized design processes: CAD automates many complex operations, helping users save time and effort. As a result, the design process is accelerated, contributing to faster project completion.

- High precision: CAD’s built-in calculation and measurement tools allow for detailed and accurate descriptions of product dimensions, shapes, and structures. This helps minimize technical errors and reduces material waste in production.

- Early error detection and correction: CAD enables design verification and adjustments from the early stages, preventing errors from occurring during actual machining.

- Enhanced collaboration: CAD software allows multiple users to work on the same drawing, making data sharing and task coordination easier, thereby improving project management and execution efficiency.

With these outstanding advantages, CAD is not just a design tool it is a foundational platform that drives accuracy, creativity, and efficiency throughout the entire modern CNC machining process.

Popular CAD software today

Today, the market offers a wide variety of CAD software, categorized into major groups to meet different design needs across various fields, specifically:

2D CAD Software

As the name suggests, 2D CAD is used to create two-dimensional technical drawings. Equipped with powerful tools for drafting, annotating, and dimensioning, this type of software is well-suited for simple, detailed design layouts. 2D CAD is widely applied in architecture, construction, and mechanical engineering, where clear representations of floor plans, elevations, or technical diagrams are required.

3D CAD Software

3D CAD allows users to create and visualize three-dimensional models from multiple angles. This enhances product visualization, making it more intuitive and accurate especially useful in designing complex components with high precision requirements. 3D CAD is commonly used in manufacturing, product design, mechanical engineering, aerospace, and various other high-tech industries.

What are the Advantages of CAD?

Based on the role and significance of CAD software in the CNC machining field, its outstanding benefits can be clearly seen:

- Improved product quality: CAD enables the creation of highly accurate technical drawings with clear details. It is considered the most precise design tool in the machining industry, ensuring that products meet strict technical standards.

- Increased productivity and reduced design time: With its ability to automate design and machining programming processes, CAD helps users save time and effort, thereby boosting productivity and accelerating production timelines.

- Reduced production costs: Early detection and correction of design errors help minimize mistakes during machining. This reduces material waste and repair costs, contributing to more efficient budget management.

- Enhanced competitive advantage: Businesses that integrate CAD into their CNC machining processes can produce high-quality products at optimized costs and faster speeds, strengthening their competitive position in the market.

What are the disadvantages of CAD?

While CAD software offers numerous benefits in design and manufacturing, there are still some drawbacks to consider:

- High initial investment: Professional CAD software is often expensive, not to mention the additional costs for compatible hardware (high-performance computers, large monitors, input devices, etc.) and employee training fees.

- Requires specialized skills: Users need formal training to use CAD effectively. Mastering the software demands time for learning, practice, and continuous knowledge updates.

- Dependence on technology: Since CAD runs on computer systems, power outages, software malfunctions, system errors, or viruses can disrupt workflow and lead to data loss if proper backups are not maintained.

- Limited flexibility in initial creativity: Some designers feel that CAD may constrain the early stages of idea development, making it more rigid compared to the freedom of hand sketching.

- Risk of over-reliance: Excessive dependence on CAD can lead users to neglect fundamental skills such as technical drawing, manual calculations, and geometric thinking potentially weakening their ability to handle situations without software support.

Applications of CAD Software in CNC Machining

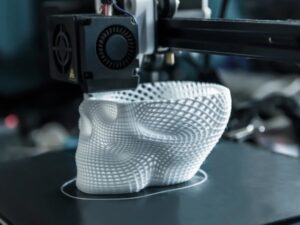

CNC machines are automated processing equipment controlled by intelligent computer systems to perform cutting operations with extremely high precision. For CNC machines to operate efficiently, the key factor lies in the machining programs generated from CAD design software. CAD provides complete technical information about the product—from shape and dimensions to cutting sequences enabling the CNC machine to carry out each step of the machining process accurately.

As a result, CAD has become an essential tool across many CNC machining fields, including:

- Mechanical Engineering: CAD is used to design mechanical components such as shafts, gears, and engine housings with high precision and customization according to production requirements.

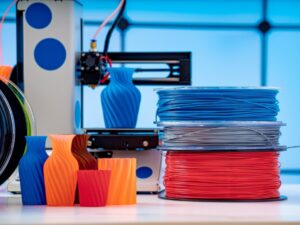

- CNC Mold Making: CAD supports the design and simulation of molds for plastic and metal products, contributing to the optimization of mass production processes.

- Electronic component manufacturing: CAD is applied in designing circuit boards, chips, and complex electronic parts, ensuring absolute accuracy down to the smallest details.

- 3D engraving and artistic modeling: CAD enables the creation of intricate 3D models for CNC metal engraving or shaping various materials used in decorative and artistic products.

Using CAD in design and machining not only enhances precision and saves time but also optimizes production costs and boosts a company’s competitiveness. With the outstanding benefits outlined above, you now have a clearer understanding of what CAD is and its vital role in modern industrial sectors.

If you’ve completed your 3D design file but lack the equipment for printing or need CNC machining services after the design phase contact 3Dmanufacturer today!

We not only offer high-quality 3D printing services but also provide Reverse Engineering and Product Inspection services to help you complete your manufacturing process in a professional and optimized manner.

Ready to turn your CAD designs into reality?

Contact 3Dmanufacturer (3Dm) for expert 3D printing, CNC machining, reverse engineering, and product inspection services. We’ll help you complete your manufacturing process professionally, efficiently, and cost-effectively.