3D printing technology has been around since the 1980s and is now emerging as one of the most revolutionary technologies across various industries. With the ability to turn ideas into tangible products in a short time, 3D printing not only streamlines production processes but also unlocks new opportunities for innovation—regardless of business size. So, what exactly is 3D printing, and why is it considered a game-changing force that could reshape the way the world operates?

Discover more about this groundbreaking technology in the article below, brought to you by 3Dmanufacturer.

What Is 3D Printing?

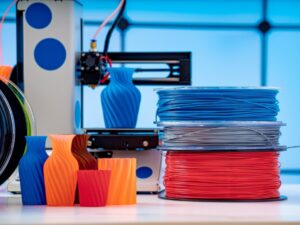

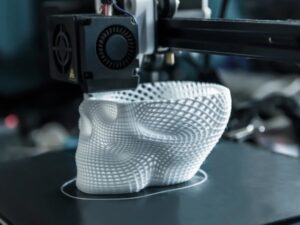

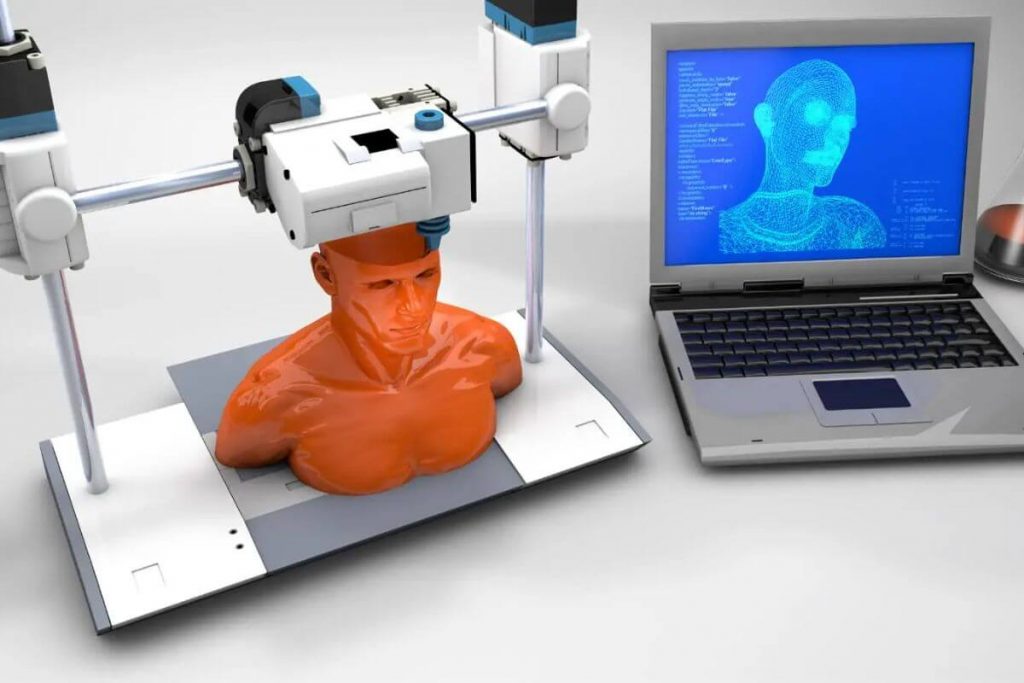

Unlike traditional 2D printing—which prints on a single flat layer, typically on paper—3D printing is a process that builds objects layer by layer based on a digital 3D model. It uses an additive manufacturing technique to create physical prototypes or final products by stacking layers of material on top of each other. This technology is executed automatically through specialized 3D printers, delivering high-precision results in just a few hours.

3D printing empowers businesses, creators, and designers to freely produce highly complex parts at a much lower cost compared to traditional prototyping methods. Depending on the specific printing technology and application, the materials used can range from metals to various types of plastics or resins.

The Unique Benefits of 3D Printing Technology

With its rapid and continuous advancement, 3D printing technology is becoming increasingly popular and widely adopted across various industries—including healthcare, automotive manufacturing, education, construction, fashion, art, and even culinary arts. This technology helps break the traditional boundaries of production, unlocking new potential in product innovation, process optimization, and cost efficiency.

Here are some of the most outstanding benefits that 3D printing brings to the table:

Accelerate Production Speed

In today’s competitive market, where time-to-market can determine a company’s survival, 3D printing serves as a powerful key to gaining that critical edge—driving innovation and success.

Imagine this: when developing a new product concept, instead of spending weeks or even months navigating a complex and costly prototyping process to produce a small number of test models, 3D printing can deliver functional prototypes in just a few hours. This unmatched speed—something no other manufacturing method can rival—transforms intricate digital designs into physical models almost instantly. As a result, businesses can quickly evaluate, refine, and move forward with their product ideas in a much shorter timeframe.

Ensure Prototype Quality

In traditional manufacturing, prototype development can sometimes suffer from design flaws caused by human error—leading to uncertainty about the final product’s quality.

3D printing eliminates much of this risk by enabling the creation of highly detailed and accurate prototypes. This technology ensures that each model meets the exact design and engineering specifications, giving businesses greater confidence in the quality and functionality of their products.

Cost Efficiency

Traditional manufacturing often requires a large, skilled workforce to operate machinery, perform injection molding, and manage various production stages—resulting in significant operational costs.

In contrast, 3D printing streamlines the process. With just a single operator to initiate the print job, this advanced technology can deliver the same expected results at a fraction of the cost. Moreover, material usage is optimized thanks to high-precision output and the ability to reuse printed parts or leftover materials—helping reduce waste and further lower expenses.

Turn Ideas into Reality—in Just Hours

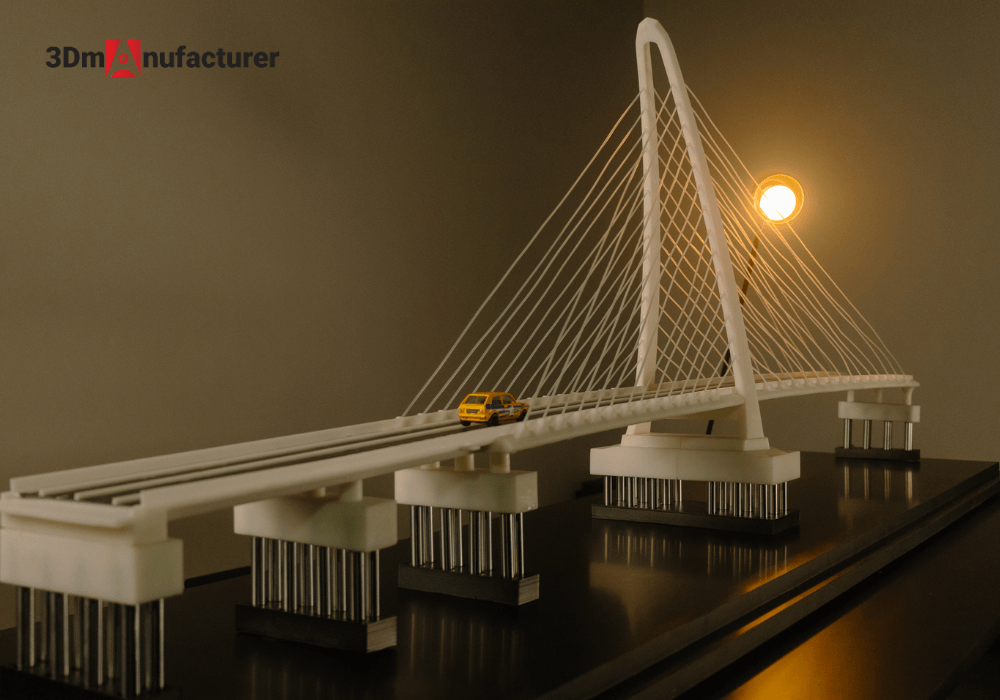

With virtually unlimited customization, near-perfect precision, and the ability to print using hundreds of different materials and colors, 3D printing is fully equipped to meet even the most complex and technically demanding requirements.

By removing traditional production barriers, this technology makes it easier than ever to transform customer-specific ideas into tangible products. Creators can now visualize the future—where the gap between concept and reality is just a matter of hours.

With 3D printing, creativity knows no bounds. The only limit is your imagination.

Common 3D Printing Technologies

Today, 3D printing has evolved into a range of specialized techniques, each designed to meet diverse needs across manufacturing and design. Some of the most commonly used technologies include:

– FDM (Fused Deposition Modeling): Builds objects layer by layer using melted thermoplastic filament.

– SLA (Stereolithography): Uses UV lasers to cure liquid resin with exceptional precision and surface quality.

– SLS (Selective Laser Sintering): Uses a high-powered laser to fuse powdered materials like nylon, creating strong and functional parts.

– DMLS (Direct Metal Laser Sintering): Enables direct metal printing with outstanding strength and detail—ideal for aerospace, medical, and automotive applications.

Each method offers unique advantages, contributing to the power and versatility that make 3D printing one of today’s most transformative technologies.

3D Printing: The Future of Innovation

Thanks to its proven, real-world benefits, 3D printing is rapidly becoming a driving force across industries. More and more businesses are adopting this transformative technology to enhance flexibility, accelerate production, and reduce costs.

By turning even the most complex ideas into reality—with remarkable precision, speed, and cost efficiency—3D printing is expanding its presence across sectors and contributing significantly to the global economy.

Today, the question “What is 3D printing?” goes far beyond definitions. It opens the door to a world of practical applications that empower both businesses and individuals to innovate faster, smarter, and more economically than ever before.

If you’re looking for a reliable 3D printing partner—from rapid prototyping and small-batch production to technical design consultation—3Dmanufacturer (3Dm) is ready to support you every step of the way.

Contact us today to unlock the full potential of 3D technology.