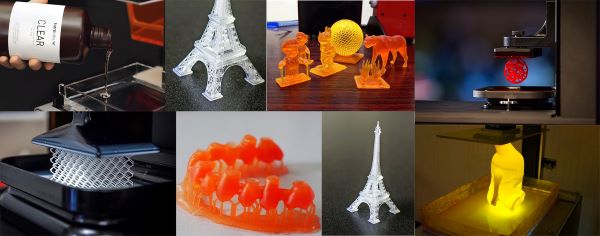

What is resin and why is this material becoming increasingly popular in 3D printing technology? Resin, also known as photopolymer, is a type of 3D printing material capable of producing highly detailed products with smooth surfaces and complex shapes. Thanks to its outstanding advantages, resin has been widely applied in various fields such as product prototyping, digital dentistry, jewelry making, and model manufacturing.

What is resin plastic?

Resin material is a compound derived from organic substances, typically found in a thick liquid form with high viscosity. It can be extracted from plants or synthesized through chemical processes, capable of polymerizing into solid polymers. Resin often serves as an additive in other plastic-based material systems.

What are the key characteristics of resin?

Below are some outstanding features that make resin a widely used material across various fields:

- High viscosity: Makes resin suitable for various construction techniques and industrial applications.

- Polymerization capability: Resin can cure into a solid, durable polymer, resulting in a high-strength final product.

- Flexible origin: It can be either synthetically produced or naturally extracted from sources like tree sap.

- Diverse physical properties: Depending on the intended use, resin can exist in liquid, solid, or powder form.

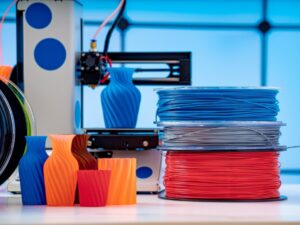

Types of resin used in 3D Printing

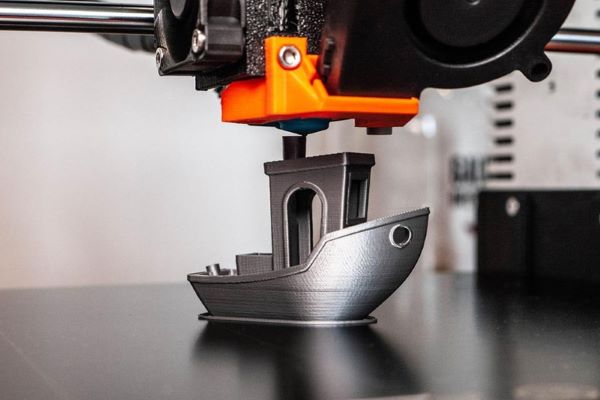

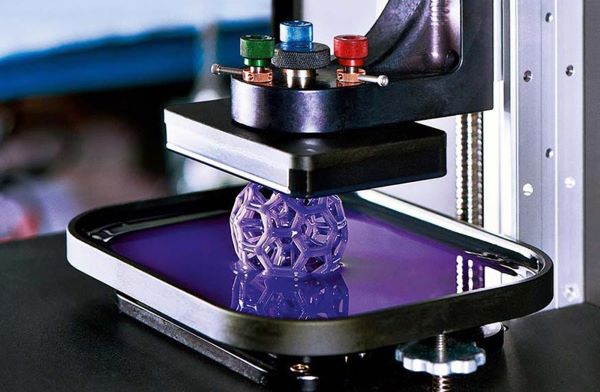

3D printing resin is a crucial material in additive manufacturing, especially suitable for light-based technologies such as SLA (Stereolithography Apparatus) and DLP (Digital Light Processing). With its ability to produce high-detail and highly accurate prints, resin is widely applied in various creative and technical fields. Below are some common types of 3D printing resin:

- High-detail Resin: Designed for prints requiring high sharpness and fine detail, commonly used in architectural models, jewelry making, or technical prototypes.

- Paintable Resin: Features a smooth surface that is easy to paint, ideal for artistic products, decorative models, or aesthetically finished parts.

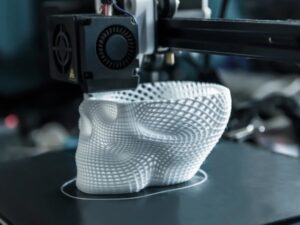

- Transparent Resin: Enables printing of transparent objects, suitable for medical simulations, optical devices, or products that require internal visibility.

- ABS-like Resin: Mimics the characteristics of ABS plastic used in FDM technology. This type of resin is durable, flexible, and heat-resistant ideal for technical components or products requiring high mechanical strength.

- PLA-like Resin: Similar to PLA plastic, this resin is easy to print, environmentally friendly, and highly accurate, though brittle suitable for detailed, low-stress applications.

- Tough Resin: Offers superior strength and impact resistance compared to standard resin, with reduced brittleness ideal for mechanical parts and engineering components.

- Flexible Resin: Highly elastic and flexible, capable of bending without cracking perfect for products like handles, gaskets, or soft components.

What are the advantages and disadvantages of 3D printing resin?

3D printing methods using resin are highly diverse, with each technology offering distinct characteristics. Printing performance depends on various technical factors such as light source power, build volume, machine operation mechanism, and the physical and chemical properties of the resin used.

Advantages of 3D printing resin

Resin is increasingly establishing its superior position in the field of 3D printing thanks to its outstanding advantages, unmatched by many other materials. With its ability to meet strict requirements in terms of quality, detail, and performance, resin offers significant benefits for both rapid prototyping and precision manufacturing. Specifically, the key strengths of 3D printing resin include:

- High detail and accuracy: Resin enables the creation of sharp, high-resolution products, ideal for small and complex parts such as engineering models, dental components, or jewelry.

- Smooth and aesthetic surface finish: Resin-printed products typically have smooth surfaces with virtually invisible layer lines, minimizing the need for post-processing and enhancing visual appeal.

- Fast printing speed: Resin printing technologies especially SLA and DLP can achieve superior speeds, making them suitable for rapid prototyping and quick production of finished parts.

- Cost-effective for certain applications: Resin is an economical option for high-quality but small-scale production, particularly in fields like rapid prototyping, digital dentistry, and jewelry modeling.

- Wide variety of material types: From rigid, flexible, and transparent resins to those with elastic or high-strength properties, the diversity of resin types allows users to adapt to various applications.

- Good water resistance: Resin is non-hygroscopic, giving printed products excellent water resistance ideal for applications exposed to moisture or requiring waterproof properties.

Disadvantages of 3D printing resin

Despite its many outstanding advantages, resin also has certain limitations that users should consider when selecting it for 3D printing applications. Notable drawbacks include:

- Limited mechanical strength: Resin-printed parts are generally more brittle and less impact-resistant compared to materials like ABS or PLA, especially in load-bearing applications.

- High cost: Compared to other 3D printing methods like FDM, resin printing requires specialized equipment and higher-priced materials, resulting in increased investment and operating costs.

- Toxicity: Liquid resin can cause skin irritation or pose health risks if not handled properly. Users must wear gloves, masks, and ensure proper ventilation during use.

- Complex post-processing requirements: After printing, parts must be cleaned with isopropyl alcohol, cured under UV light to achieve full mechanical properties, and may require sanding making the process time-consuming and labor-intensive.

- Poor heat resistance: Resin typically lacks thermal stability and may deform or degrade when exposed to high temperatures, limiting its use in certain specialized environments.

Practical applications of 3D printing resin

3D printing resin stands out not only for its high-quality, detailed prints but also for its wide range of applications across various industries. From product prototyping to dentistry, jewelry, and architectural modeling, resin offers an efficient and versatile printing solution.

- Product prototyping: Resin is an ideal choice for rapid prototyping thanks to its ability to reproduce sharp details and high precision. Designers and engineers can use resin to print product prototypes for testing shape, functionality, and finish before moving into mass production. This helps optimize costs and shorten product development time.

- Dental field: In digital dentistry, resin is used to accurately print structures such as dentures, dental models, crowns, bridges, and orthodontic devices like brackets or clear aligners. These products not only ensure high aesthetics but also provide a realistic and comfortable experience for users. Additionally, resin-printed dental models are used in orthodontic procedures, dental implant planning, and professional training.

- Jewelry making: With its ability to reproduce extremely small and intricate details, resin is particularly well-suited for the jewelry and fine jewelry industry. Castable resin is a specialized type designed for mold casting, capable of burning out completely without leaving residue, allowing for the creation of precise and detailed molds. Additionally, resin can be colored or surface-finished to produce vibrant, glossy, and uniquely styled jewelry prototypes.

- Model printing: Resin is an ideal material for producing highly detailed models such as architectural models (buildings, dioramas), character figures from animation, comics, and films, children’s toys, or educational models used in teaching. Thanks to its flexible shaping ability and high precision, resin brings complex designs to life with vivid and sharp detail.

From its wide range of practical applications to its ability to produce highly precise and aesthetically pleasing products, resin is increasingly asserting its vital role in modern 3D printing. Understanding what resin is not only helps users choose the right material for their needs but also opens up new opportunities for creativity and production optimization in the future. Resin offers outstanding advantages in detail and surface smoothness and 3Dm is the perfect partner to fully harness the potential of this technology.

As the first automated 3D printing platform in Vietnam, 3Dm utilizes advanced printing technologies and supports resin materials to deliver sharp, high-precision products. Whether you need to prototype a product, craft jewelry, or create dental applications, we are ready to meet all your demands. Contact 3Dm today to experience high-quality 3D printing services that optimize both cost and production time!