Resin plastic is one of the most popular 3D printing materials today due to its ability to produce sharp, smooth, and highly detailed products. So, what exactly is resin plastic? And why is this material so highly regarded? This article from 3Dmanufacturer will help you better understand the characteristics, properties, and fascinating practical applications of resin in 3D printing.

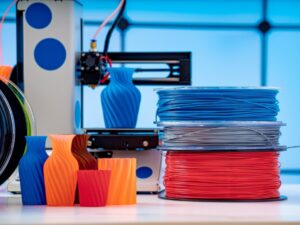

What is 3D Printing Resin?

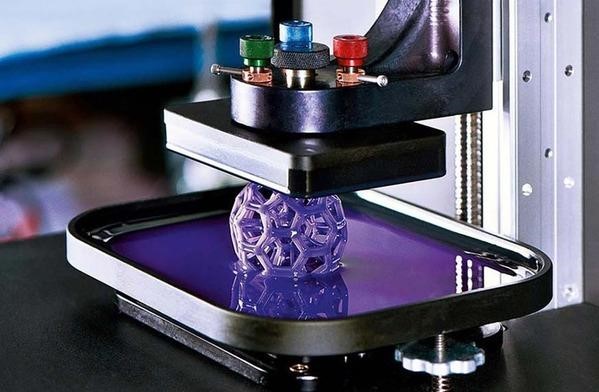

Resin is a type of polymer that exists in liquid form, commonly referred to as a photopolymer. This resin is primarily used in advanced 3D printing technologies such as SLA (Stereolithography) and DLP (Digital Light Processing), both of which rely on light to process the material.

When exposed to UV light or light of a suitable wavelength, the resin reacts and gradually hardens layer by layer. Thanks to this characteristic, resin can produce extremely precise and sharp printed details – something that many other 3D printing technologies find challenging to achieve.

Depending on the type of resin and the printing technology used, users can create a wide variety of 3D products from the same original design, such as technical models, jewelry, or intricate medical models.

Types of 3D Printing Resin

Based on chemical composition, raw material sources, and technical properties, 3D printing resin is divided into three main groups, each suited for different needs and purposes:

- High-Detail Resin: This specialized resin is used for products requiring high precision and sharp details. High-detail resin is commonly applied in miniature modeling, jewelry crafting, and printing intricate parts.

- Paintable Resin: This type of resin is suitable for products that require surface finishing with paint. Paintable resin features a smooth surface, is easy to process after printing, and supports painting and coating steps to achieve glossiness and enhanced aesthetics.

- Transparent Resin: This type of resin is ideal for applications requiring high clarity, simulating real materials such as glass, crystal, or optical components.

Key Features of Resin

Resin is a popular 3D printing material thanks to its ability to produce sharp details, smooth surfaces, and high accuracy in each printed layer. Finished products printed with resin typically have superior surface quality compared to other 3D printing technologies using conventional filament.

Below are some notable characteristics of this material that should not be overlooked:

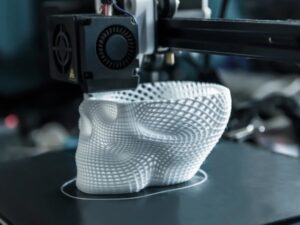

How Does 3D Printing with Resin Work?

The 3D printing process using resin involves the following precise and sequential steps:

- Resin Vat: The resin is poured into the vat either manually or via an automated system. If done manually, it is recommended to wear protective gloves to avoid direct skin contact, as some types of resin may cause irritation or toxicity if not handled properly.

- Build Platform: The build platform moves up and down layer by layer to immerse into the thin resin layer during printing.

- Light Source: A UV beam (typically from LED or laser) passes through a digital mask (DLP/LCD) or is directed by a mirror system (SLA) to cure each resin layer into the desired shape.

- Platform Movement: After each resin layer hardens, the build platform shifts to allow the next layer of liquid resin to flow and prepare for the next printing cycle.

After the printing process completes, the product is removed from the build platform and undergoes post-processing steps such as washing, drying, or UV curing to enhance durability.

Is 3D Printing Resin Harmful to Health?

By nature, all types of 3D printing resin harden when exposed to UV light. During the chemical reaction, resin can generate heat and release some volatile compounds that may emit unpleasant odors or even cause skin irritation upon direct contact. Therefore, using rubber gloves, masks, protective goggles, and proper ventilation systems is essential to ensure safety when printing with 3D resin.

Nowadays, many epoxy-free resin variants are available on the market, significantly reducing toxicity and odor. With these types of resin, users can confidently operate 3D printers right on their work desks without worrying much about health issues.

Some Common Applications of Resin

Thanks to its hardness, durability, moldability, and smooth surface, resin is widely used to create unique and intricate products across various fields such as jewelry, dentistry, and model making.

Jewelry (Goldsmithing)

The combination of 3D printing technology and the jewelry industry has opened a new era for crafting jewelry. Resin acts as an intermediary material in mold creation, helping jewelers quickly and accurately realize digital designs.

- Direct Casting: One popular resin type in casting techniques is Jamghe High Wax Resin, which contains up to 70% wax. This resin offers surface quality nearly equivalent to traditional casting wax (such as wic100a), with high detail resolution, ease of shaping, and maximum design flexibility.

- Mold Making: Resin Jewelry Mold is a specialized resin used to create molds with high mechanical strength, excellent impact resistance, perfectly smooth surfaces, elasticity, and flexibility – ideal for repeated mold reuse in jewelry production.

In the Dental Industry

The dental field is witnessing a surge in 3D printing technology, where resin plays a key role as the primary material. Many resin types have received FDA biocompatibility certifications and can perfectly replace traditional materials due to their high accuracy and durability.

- Dental Models: Resin is used to print orthodontic models, crowns and bridges, and removable prosthetic models. A recommended choice is Jamghe Standard 10K Resin, a standard resin known for high accuracy, clear details, smooth surfaces, environmental friendliness, absence of toxic solvents, and reasonable cost.

- Temporary Teeth: Used for temporary dentures while waiting for the final restoration. Jamghe Temporary C&B Resin is FDA-certified safe, BIO organic standard compliant, non-toxic, and durable enough for continuous use over several days.

- Dental Casting Wax: Used to create frameworks, crowns, removable frameworks, and metal castings. Jamghe Dental Castable Resin is a specialized resin with high accuracy, low odor, stable performance, compatible with most LCD and DLP printers. It meets REACH, ROHS, EN71-3 standards and has an extremely low shrinkage rate (0.85 – 1.0%).

- Surgical Guides: Used to print surgical guides, drilling templates, and precision instruments for implant procedures. Jamghe Surgical Guide Resin is transparent, FDA Class I medical device certified, and compliant with ISO 10993 standards. Its minimal flexural strain helps printed models maintain shape throughout surgical interventions.

- Gingival Masks: Combined with dental models to simulate soft tissue in the oral cavity, aiding implant placement, orthodontics, and crown-bridge design. Jamghe Flexible Plus Resin is highly elastic, easy to trim, providing a snug and realistic fit. Its translucent pink color accurately mimics patients’ gum tissue conditions.

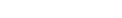

Model Making, Design, and Toy Manufacturing

In the field of model design and production, resin allows for the reproduction of small, intricate details that many other 3D printing methods struggle to achieve. Because of this advantage, designers, film studios, and toy manufacturers utilize resin to transform digital 3D models into sharp, physical products, serving both production and display purposes.

Advantages and Disadvantages of 3D Printing Resin

Resin is a widely used material in 3D printing technology thanks to its ability to produce highly detailed and smooth-surfaced products. However, like any material, resin has its own strengths and limitations that should be considered when choosing it.

Advantages of 3D Printing Resin

Some notable advantages of 3D printing resin include:

- Sharp Details and High Accuracy: Resin is introduced into the printer in liquid form, enabling superior reproduction of complex details compared to FDM printing that uses filament. This allows resin prints to achieve exquisite sharpness with tiny details that other methods find difficult to replicate.

- Smooth Surface Finish: Although layer lines may still appear when printing with resin, they are very fine – sometimes nearly invisible depending on the resin color – resulting in a much smoother and more aesthetic final product than FDM printing.

- Wide Range of Materials to Meet Needs: There is now a vast variety of resins available on the market suitable for diverse applications, from artistic models, jewelry, and medical uses to technical parts. The resin material catalog continues to expand to meet the growing and varied demands of users and industries.

- Supports Without Surface Damage: The resin vat in the printer is completely filled, allowing small details or “floating” parts to securely attach to the main body during curing, preventing surface damage or deformation.

- Fast Printing Speed and High Efficiency: Compared to traditional 3D printing methods, resin technology offers much faster printing speeds, especially with modern machines, delivering impressive productivity and shortening model completion time.

- Cost-Effective: While resin can be more expensive than some other printing materials, in many cases such as prototyping, custom dental devices, or jewelry models, resin printing proves to be a cost-effective choice compared to traditional methods.

- Good Water Resistance: Compared to thermoplastics or powder-based materials, resin has better hardness and water resistance. Resin products do not absorb moisture from the air, making them suitable for parts requiring waterproof properties or use in humid environments.

Disadvantages of 3D Printing Resin

Alongside its advantages, 3D printing resin has some limitations, including:

- Limited Print Size: Most resin printers currently have small build volumes. Producing large models becomes costly and challenging as it requires specialized industrial equipment. Additionally, filling expensive resin vats for large prints significantly increases production costs.

- Strict Design Requirements: Resin printing requires a complete design prepared beforehand or during production setup. To ensure the best print quality, models must be tilted approximately 45 degrees relative to the print bed and avoid direct contact with the bed surface.

- Complex Post-Processing: The finishing process for resin prints involves at least three essential post-processing steps: cleaning excess resin, curing under UV light for full hardening, and removing support structures. These steps are crucial to guarantee the final product’s quality and durability.

- Continued Curing After Printing: After printing, chemical reactions in the resin continue, which may cause shrinkage, cracking, or deformation depending on the material composition and handling. Users need to carefully control this to avoid negatively affecting product quality.

- High Investment Cost for Printers: Owning a quality desktop resin printer typically costs between $3,500 and $4,000, while resin material costs around $100–$200 per liter. Industrial-grade printers can cost significantly more, ranging from $80,000 to $250,000.

- Resolution Depends on Multiple Factors: The quality and resolution of resin prints depend not only on the printer but also on the resin type, model orientation, firmware settings, and other technical parameters. Achieving optimal results requires users to understand and manage these variables carefully.

Important Safety Notes When Using Resin

Resin is a popular 3D printing material known for its high detail, but it also comes with strict safety requirements during use. To ensure effective results and avoid unwanted risks, users should keep the following points in mind:

- Store resin in a safe place, out of reach of children.

- When handling resin, wear nitrile gloves or other specialized protective gloves to prevent direct skin contact.

- Resin can cause severe reactions if it comes into contact with skin or mucous membranes, especially the eyes. If resin gets into the eyes, rinse immediately with clean water continuously for at least 15 minutes and seek medical attention as soon as possible.

- Resin should be stored in a dry, well-ventilated environment with an ideal temperature range between 15°C and 30°C. Proper storage not only extends the material’s shelf life but also ensures consistent printing quality.

We hope that through the insights shared in this article, readers now have a clear understanding of resin plastic, its advantages and disadvantages, as well as some typical applications of resin in 3D printing. If you are looking for a quality and competitively priced resin supplier, 3Dmanufacturer is the ideal choice. Discover the specialized resin product lines at 3Dmanufacturer today to take your 3D printing projects to the next level!