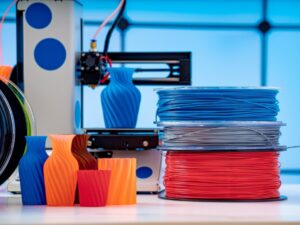

Many print failures, which may appear to result from machine malfunctions or design flaws, are actually caused by improper 3D printing filament storage. Moisture absorption, material degradation, or chemical changes during storage can significantly impact print quality. In this article, 3Dmanufacturer provides detailed guidance and practical tips to help you store your filament correctly and keep it in optimal condition.

The importance of proper 3D printing filament storage

Proper 3D printing filament storage directly affects the reliability of your prints, material usage, and maintenance workload. Understanding the risks of improper storage is essential for both hobbyists and professionals.

Prevent moisture absorption and print defects

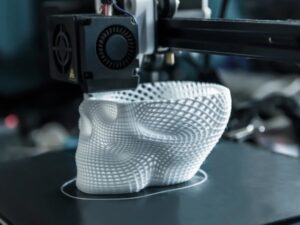

Most 3D printing filaments (especially Nylon, PETG, TPU, PC) absorb moisture quickly from the air. When filament becomes damp, the water vaporizes during extrusion, creating bubbles and voids that result in rough print surfaces, poor layer adhesion, and delamination.

Cost savings

If a filament spool is damaged due to moisture absorption, oxidation, or dust contamination, you may have to discard the entire roll or spend a lot of time troubleshooting print issues. Proper storage helps minimize waste and significantly reduces material costs in the long term.

For example, a damaged spool of specialty filament like Nylon or carbon-filled materials can cost $50 – $100 per roll – losing one due to poor storage is a waste both financially and operationally.

Ensure health and safety

Some types of filament, such as ABS, liquid resin (used in SLA technology), or materials with special additives, can emit toxic gases (like styrene, VOCs…) when degraded in humid or high-temperature environments. Careful storage reduces the risk of exposure to these compounds during printing.

Prevent printer damage

Improperly stored filament can directly impact your 3D printer. Moisture-laden filament releases steam during extrusion, which may clog the nozzle, wear out the extruder gear, or cause motor missteps. Over time, these issues accelerate wear and tear, reduce equipment lifespan, and increase maintenance costs.

How to store 3D printing filament properly?

3D printing filament storage plays a crucial role in preserving material quality and ensuring smooth printer operation. To keep your filament in optimal condition and extend both its usability and your printer’s lifespan, follow these proven storage methods:

- Store in an airtight container or bag: Keep filament in sealed plastic boxes or zip-lock bags that fit the spool and have moisture barriers. This limits air exposure and helps prevent humidity from entering. It’s a simple yet effective way to protect filament from environmental damage, especially when not used frequently.

- Use desiccant packs: Place silica gel or specialized desiccant packets inside the storage container to absorb moisture. This is particularly important for filaments like Nylon and PETG, which are highly hygroscopic. Regularly check and replace the desiccant to maintain low humidity and protect filament quality.

- Use vacuum-sealed bags: Vacuum sealing removes almost all air inside the bag, offering excellent long-term moisture protection. This method is ideal for storing high-value or rarely used filaments. Vacuum bags with resealable valves also make it convenient to reuse after each printing session.

- Use foam boxes or insulated containers: Thick foam boxes or insulated containers are budget-friendly solutions that shield filament from light and temperature fluctuations. They help maintain a more stable micro-environment, especially useful in areas with high humidity or inconsistent climate conditions.

- Invest in dedicated storage cabinets: For those with multiple spools, a humidity-controlled cabinet or storage box with temperature and humidity regulation is a great investment. These cabinets ensure long-term, stable storage, protect your materials, and reduce the risk of print failures due to filament degradation.

- Maintain stable storage temperatures: Filament should be stored in cool, stable environments, ideally between 15°C and 30°C. Avoid placing spools near heat sources or in areas exposed to cold drafts, as temperature swings can accelerate moisture absorption and cause material deformation over time.

- Avoid sunlight and UV exposure: Long-term exposure to sunlight or UV rays can cause filament to become brittle, discolored, or warped. Always store filament in shaded areas or use UV-blocking covers to preserve material integrity and ensure consistent printing performance.

Additional tips for storing 3D printing filament

Proper 3D printing filament storage goes beyond just using airtight containers – it also involves good usage habits and routine maintenance. To keep your filament in optimal condition and ensure smooth, high-quality prints, consider the following additional tips:

- Use filament regularly: Using filament frequently limits the chance for moisture or dust to affect material quality during storage. Long idle periods can lead to degradation, especially in humid environments. Plan your printing schedule to rotate materials regularly and avoid leaving spools unused for extended periods.

- Trim excess filament before storage: Before storing a used spool, cut off the exposed ends of the filament. These sections may have absorbed moisture or oxidized, which can negatively impact print quality. Trimming helps ensure that only fresh, clean filament is used during your next printing session.

- Label spools with basic information: Add labels to each spool with details such as filament type, print temperature, speed, and purchase date. Clear labeling makes it easier to identify materials at a glance, manage inventory, and select the right filament for specific print jobs.

- Clean the nozzle after every print: Residual filament or dust buildup in the nozzle can reduce print quality and strain the printer’s extruder. Regular cleaning after each print helps maintain smooth filament flow, extends equipment lifespan, and prevents future clogs or mechanical issues.

- Monitor storage humidity: For long-term storage, use a hygrometer to track humidity levels in your storage area. If the environment is too humid, consider using a dehumidifier or a sealed dry box to keep filament in optimal conditions and prevent moisture absorption.

- Consider lubricants if necessary: Certain specialty filaments may require lubrication to improve feeding or adhesion. If needed, apply suitable lubricants sparingly, but always check the manufacturer’s recommendations to avoid damaging your printer or compromising print quality.

If you’re concerned about improper filament storage or don’t have access to specialized storage equipment, using 3D printing services from 3Dmanufacturer is an optimal solution. We ensure strict quality control of all printing materials, delivering sharp prints with high mechanical strength and excellent surface finish.

3Dmanufacturer serves all types of customers – from individuals and small to medium-sized businesses to large corporations. Whether you need a single prototype or mass production, we are ready to meet your needs with a professional 3D printing workflow.

- Easy online ordering: Simply upload the 3D file you need printed, and we’ll process it right away.

- Wide range of materials supported: PLA, ABS, TPU, Amber Resin, Clear Resin, and more.

- Compatible with STL files from major CAD software: SolidWorks, ProE, AutoCAD 3D, etc.

- Applications across industries: architecture, education, healthcare, automotive, aerospace, and beyond.

3D printing filament storage is a crucial step if you want to maintain consistent print performance and high-quality output. Proper storage helps prevent printing defects, reduces material waste, and extends the lifespan of your 3D printer. Or, if you’re looking for a fast, precise, and material-quality-assured 3D printing solution, let 3Dmanufacturer handle it for you!

3D printing filament storage is a crucial step that should not be overlooked if you want to ensure consistent print quality and extend the lifespan of your equipment. By applying the tips shared in this guide from 3Dmanufacturer, you can minimize print defects, reduce material waste, and keep your printing process running smoothly. Don’t underestimate the impact of proper storage – small efforts lead to better results.