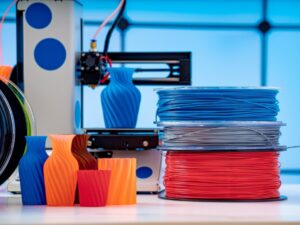

What is ABS plastic and why is it favored in 3D printing and industrial manufacturing? With its durability, excellent impact resistance, ease of processing, and high heat resistance, ABS (Acrylonitrile Butadiene Styrene) has become one of the most widely used materials today. Not only is it extensively applied in 3D printing technology, but ABS plastic is also used in industries such as electronics, automotive, healthcare, and consumer products due to its versatility and cost-effectiveness.

What are ABS plastic pellets?

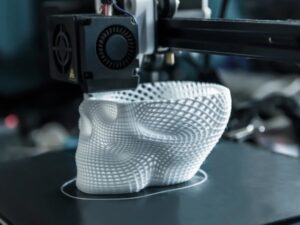

Many people wonder what ABS plastic material is. ABS (Acrylonitrile Butadiene Styrene) is one of the most widely used plastic filaments in today’s 3D printing technology, especially in FDM printers. It is a thermoplastic material composed of three monomers: acrylonitrile, butadiene, and styrene. ABS stands out for its high mechanical strength and excellent impact resistance, even at low temperatures. Patented in the 1940s, ABS quickly became a preferred material in various industrial and manufacturing applications.

Outstanding properties of ABS plastic in 3D printing

ABS plastic is one of the most popular materials in the field of 3D printing, especially with FDM (Fused Deposition Modeling) technology. Its widespread use is due to the following superior properties:

- High mechanical strength: ABS stands out for its excellent tensile and impact resistance, making printed products highly durable and suitable for applications that require structural strength and consistent rigidity.

- Good heat resistance: With a heat distortion threshold of up to around 85°C, ABS can perform reliably under higher temperatures compared to many common plastics, making it ideal for components requiring heat resistance.

- Easy post-processing: ABS-printed parts can be easily post-processed through sanding, painting, or polishing, which enhances the final product’s appearance and quality.

- Strong layer adhesion: ABS offers excellent interlayer bonding, minimizing the risk of delamination and increasing the overall strength of 3D printed objects.

Thanks to these characteristics, ABS has become a top choice for various engineering applications, digital prototypes, and consumer products that demand high quality.

Key criteria for choosing a 3D printer for ABS plastic

To select an effective 3D printer for using ABS plastic that meets your needs, you should carefully consider the following factors:

- Precise temperature control: ABS plastic requires high and stable printing temperatures. Therefore, the printer must be equipped with an effective temperature control system for both the extruder and the heated bed to ensure proper layer adhesion and final product quality.

- Heated bed and enclosed build chamber: A heated print bed helps minimize warping, a common issue when printing with ABS. Additionally, an enclosed build chamber helps maintain a stable temperature, which enhances print accuracy and strength.

- Build volume and resolution: Depending on your application, choose a printer with a suitable build volume and high enough resolution to ensure clear, precise details that meet technical requirements.

- Durability and stability: A well-built, stable printer ensures smooth printing processes, reduces technical errors, and extends the machine’s lifespan.

- Brand and after-sales service: Prioritize reputable brands that offer clear warranty policies and strong technical support for long-term peace of mind.

- Price and budget: Balance features, quality, and cost to select a printer that fits your budget while still delivering effective performance.

By carefully evaluating these factors, you’ll be able to choose an ABS 3D printer that meets your needs and provides optimal results for your production or research projects.

Applications of ABS plastic in 3D printers

3D printers using ABS plastic are increasingly proving their importance across various industries, thanks to the material’s outstanding properties such as high durability, heat resistance, and ease of post-processing. Below are some typical applications of this type of 3D printer:

- Industrial manufacturing: In the manufacturing sector, ABS 3D printers are widely used to produce components and technical parts that require high durability and heat resistance. Thanks to its exceptional stability, ABS-printed parts can serve as gears, device housings, brackets, and support tools in production lines.

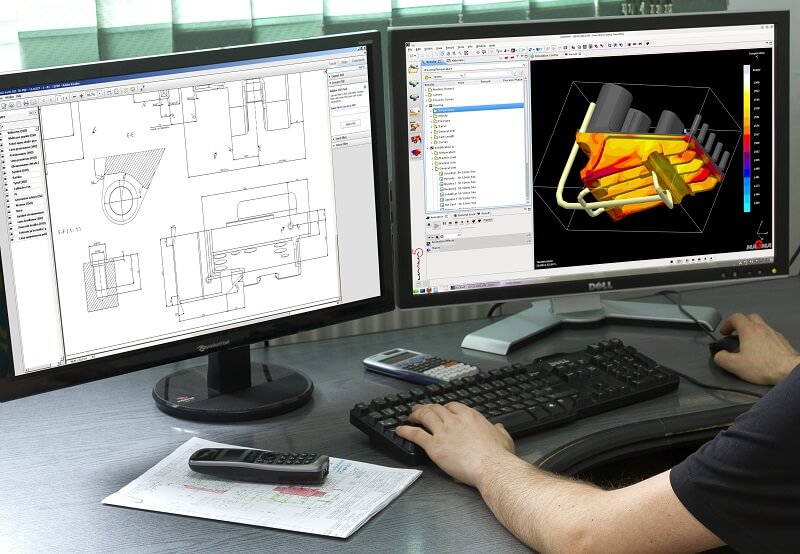

- Design and rapid prototyping: ABS is an ideal material for product development due to its ability to create strong, accurate, and easily workable prototypes. ABS 3D printers allow engineers and designers to quickly test, evaluate, and adjust designs, thereby shortening product development cycles and improving overall efficiency. Printed models can also be post-processed to closely simulate the final product.

- Education and research: In educational institutions and research centers, ABS 3D printers support students and researchers in creating visual models to illustrate technical concepts, material structures, and manufacturing processes. With high durability and good precision, ABS models enhance teaching by making it more interactive and practical.

- Healthcare: In the medical field, ABS 3D printers are used to create anatomical models, surgical tools, and medical support devices. These models allow doctors and medical students to study human anatomy in detail, prepare for complex surgeries, and practice precise procedures. Additionally, ABS is used to print durable handheld medical devices.

- Automotive and electronics industries: In the automotive industry, ABS 3D printers are applied to produce interior components such as casings, handles, dashboards, and other technical parts. This accelerates testing and development of new products at a significantly lower cost than traditional methods. In the electronics industry, ABS is an ideal choice for printing enclosures, protective covers, and structural components that safeguard electronic parts from mechanical and environmental stress.

With its combination of durability, flexibility, and wide applicability, ABS 3D printing is becoming an indispensable tool in engineering, education, healthcare, and modern industrial production.

Understanding what ABS plastic is will help you fully leverage its advantages in 3D printing and other manufacturing fields. Thanks to its high strength, heat resistance, and ease of post-processing, ABS is not only ideal for technical products but also an optimal solution for applications requiring stability and cost-efficiency.

If you’re looking for a high-quality, cost-effective 3D printing solution using ABS and other materials, 3Dm is your perfect choice. As the first automated 3D printing platform in Vietnam, we are committed to delivering fast, precise, and efficient 3D printing services. Contact us today to explore the full potential of 3D printing in your production process!